Inscription

Slag buggies, cast at the Homestake Foundry, were used in two different processes at the Homestake Refinery. One process was receiving slag produced in the blast furnace process. The Homestake blast furnace process utilized a coke-fired furnace to recover gold from waste products produced in the Refinery. Cupel (bone ash container) remains, zinc precipitate slag, broken crucibles, and litharge (lead oxide) were fired in the coke furnace. Products of this furnace were lead, which contained the gold from waste products, and barren slag. This slag was received in the slag buggy where it was allowed to cool and dumped in the form of a slag button. This slag button was then hauled to the Yates Crusher and crushed with the ore. The blast furnace process was discontinued in 1975.

The second process that used the slag buggies was the zinc precipitate reduction process. This process consisted of mixing the zinc precipitate from the cyanide process with sodium nitrate, borax, silica and soda ash and heating to approximately 2000° F in a gas fired furnace. The gold-cyanide compound was reduced to gold metal and the cyanide and zinc were oxidized and reported to the resulting slag. The melt was then poured into a slag buggy which contained a cast iron divider in the bottom. A couple minutes after the pour, the slag buggy was "dumped". The

slag was still molten and was poured onto a metal plate. The gold was solidified and was recovered as buttons of dore bullion which was processed further.

The second process that used the slag buggies was the zinc precipitate reduction process. This process consisted of mixing the zinc precipitate from the cyanide process with sodium nitrate, borax, silica and soda ash and heating to approximately 2000° F in a gas fired furnace. The gold-cyanide compound was reduced to gold metal and the cyanide and zinc were oxidized and reported to the resulting slag. The melt was then poured into a slag buggy which contained a cast iron divider in the bottom. A couple minutes after the pour, the slag buggy was "dumped". The

slag was still molten and was poured onto a metal plate. The gold was solidified and was recovered as buttons of dore bullion which was processed further.

Details

| HM Number | HM2ACF |

|---|---|

| Tags | |

| Placed By | Black Hills Mining Museum |

| Marker Condition | No reports yet |

| Date Added | Tuesday, August 14th, 2018 at 10:02am PDT -07:00 |

Pictures

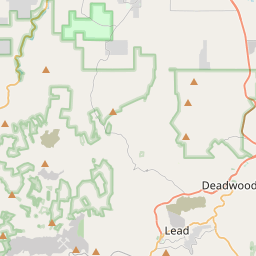

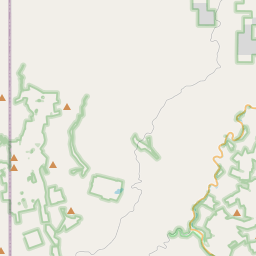

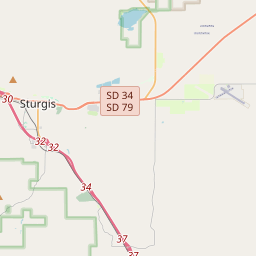

Locationbig map

| UTM (WGS84 Datum) | 13T E 598341 N 4911719 |

|---|---|

| Decimal Degrees | 44.35208333, -103.76608333 |

| Degrees and Decimal Minutes | N 44° 21.125', W 103° 45.965' |

| Degrees, Minutes and Seconds | 44° 21' 7.5" N, 103° 45' 57.9" W |

| Driving Directions | Google Maps |

| Area Code(s) | 605 |

| Which side of the road? | Marker is on the right when traveling West |

| Closest Postal Address | At or near 272 W Main St, Lead SD 57754, US |

| Alternative Maps | Google Maps, MapQuest, Bing Maps, Yahoo Maps, MSR Maps, OpenCycleMap, MyTopo Maps, OpenStreetMap |

Is this marker missing? Are the coordinates wrong? Do you have additional information that you would like to share with us? If so, check in.

Nearby Markersshow on map

Show me all markers in: Lead, SD | Lawrence County | 57754 | South Dakota | United States of America

Maintenance Issues

- Is this marker part of a series?

- What historical period does the marker represent?

- What historical place does the marker represent?

- What type of marker is it?

- What class is the marker?

- What style is the marker?

- Does the marker have a number?

- What year was the marker erected?

- This marker needs at least one picture.

- Can this marker be seen from the road?

- Is the marker in the median?

Comments 0 comments